Roval Silver

Roval Silver

ROVAL should be applied directly to metal surfaces. Direct contact between zinc and metal surface will result in cathodic reaction. Never use primer. Primers reduce the performance of Roval products. It can be applied by roller, brush, air-less spraying.

|

|

|

ROVAL‘s anti-corrosion performance is equivalent to the highest quality hot-dip galvanizing available in Japan.

In order to compare the anti-corrosion performance of ROVAL with the hot-dip galvanizing process, corrosion accelerating tests were conducted in accordance with the Japanese Standard JIS H8502-1999 in the Japan Paint Inspection and Testing Association.

The results and pictures from the test show that ROVAL has a performance equivalent to that of hot-dip galvanizing.

ROVAL has been certified by the Construction Technology Council Certification Center in Japan as equivalent to hot-dip galvanizing.

• JIS H8502-1999 is based on ISO Standards 4540,4541,8407,8565,9227 and 10062.

Miyakojima Island Test Area

Miyakojima Island Test AreaMiyakojima Island is located in the southern part of Japan, roughly at the same latitude as Florida, USA. The island is a place where high temperatures, humidity and salt content, strong sunlight and UV effect can be used to test the deterioration due to bad weather conditions.

ROVAL has the characteristics that prevent the formed rust from passing under the application layer.

On the Miyakojima island of Japan, ROVAL and other competitors’ anti-corrosion paints were exposed to atmospheric conditions at the center where deterioration from bad weather conditions was tested for 36 months.

The results show that; While ROVAL protects steel surfaces against the spread of rust by electrochemical reaction, other products have not prevented the spread of rust from cross-scratched parts to other surfaces.

ROVAL is a cold galvanizing product with high anti-corrosion performance, providing equivalent protection to hot galvanizing. ROVAL has a 96% zinc content in the dry film. ROVAL has a 96% zinc content in the dry film. |

|

ROVAL has a 96% zinc content in the dry film. Anti-corrosion performance is equivalent to hot-dip galvanizing.

High temperature is required for hot-dip galvanizing. However, ROVAL cold galvanizing can be performed even at room temperature. Ready-to-use ROVAL cold galvanizing has been used in Japan for more than half a century in the restoration of worn hot-dip surfaces and in the protection of metal surfaces such as steel against corrosion.

ROVAL cold galvanizing product shows high anti-corrosion performance with high electrochemical reaction properties of zinc.

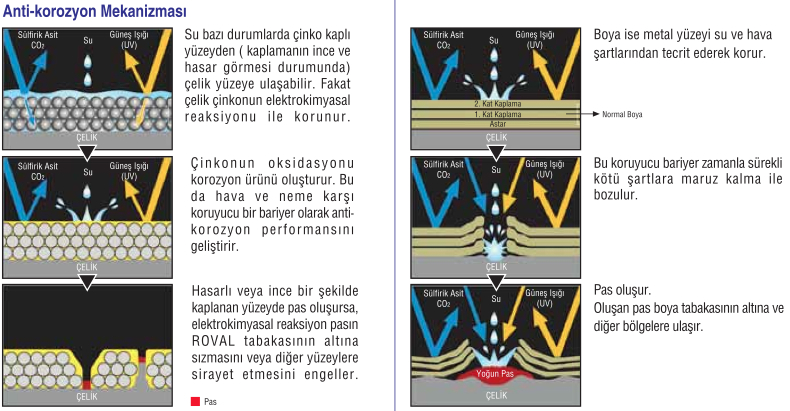

ROVAL protects steel against corrosion with its electrochemical reaction property of Zinc. Zinc provides cathodic protection on the metal surface by direct contact. The electrochemical reaction prevents the rust from seeping under the ROVAL film even if rust is formed on the damaged or finely coated surface.

Normal paints provide protection against water / air on the metal surface. If the paint layer is damaged or spilled, rust will reappear. The rust layer formed spreads from the bottom of the paint to the other regions.

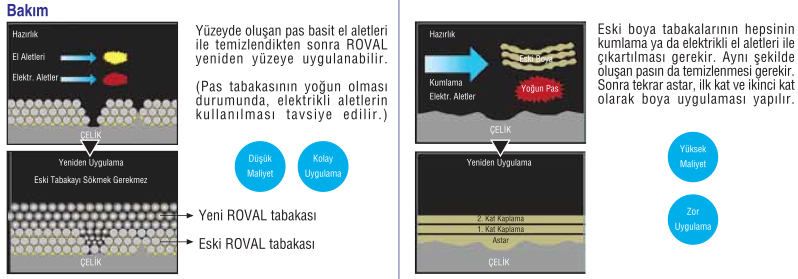

ROVAL can be applied directly to the surface only after the rust formed in the damaged area is removed. The new layer applied fuses with the old layer regardless of the time passing. A different layer does not occur. This significantly reduces maintenance costs.

| ROVAL (Anti-corrosion with Electrochemical Reaction) | Normal Paints (Anti-corrosion with Barrier protection) |

|

|

|

|

Roval products have the same properties as galvanized materials exposed to weather conditions. These characteristics make the repair invisible.

The Gladiator System consists of a portable unit applied by flame spraying thermoplastic powders for anti-rust treatments.

The system, used with Propane gas, LPG, etc., and compressed air, also has various accessories depending on the nature of the work.

The system is resistant to sun, sand, salt, water, and substances causing common air pollution and chemical agents, while providing long-lasting anti-rust coating properties resistant to impacts, low temperatures, and UV rays. The product can be applied without using a primer. Perfect consistency in color is guaranteed. Gladiator has a wide range of application areas in various sectors;

Buildings and bridges, offshore structures, and applications exposed to marine conditions, etc.

Lighting poles, railings, fences, playground structures, swimming pools, gas/water distribution systems, food industry.

The Gladiator System provides numerous benefits in application along with superior efficiency and quality performance:

Does not contain VOCs, halogens, isocyanates, and heavy metals, thus ensuring: