NEW SOLUTIONS IN THE ANTI-CORROSION COATINGS INDUSTRY

GLADIATOR: The Most Effective Technology to Prevent Surface Degradation

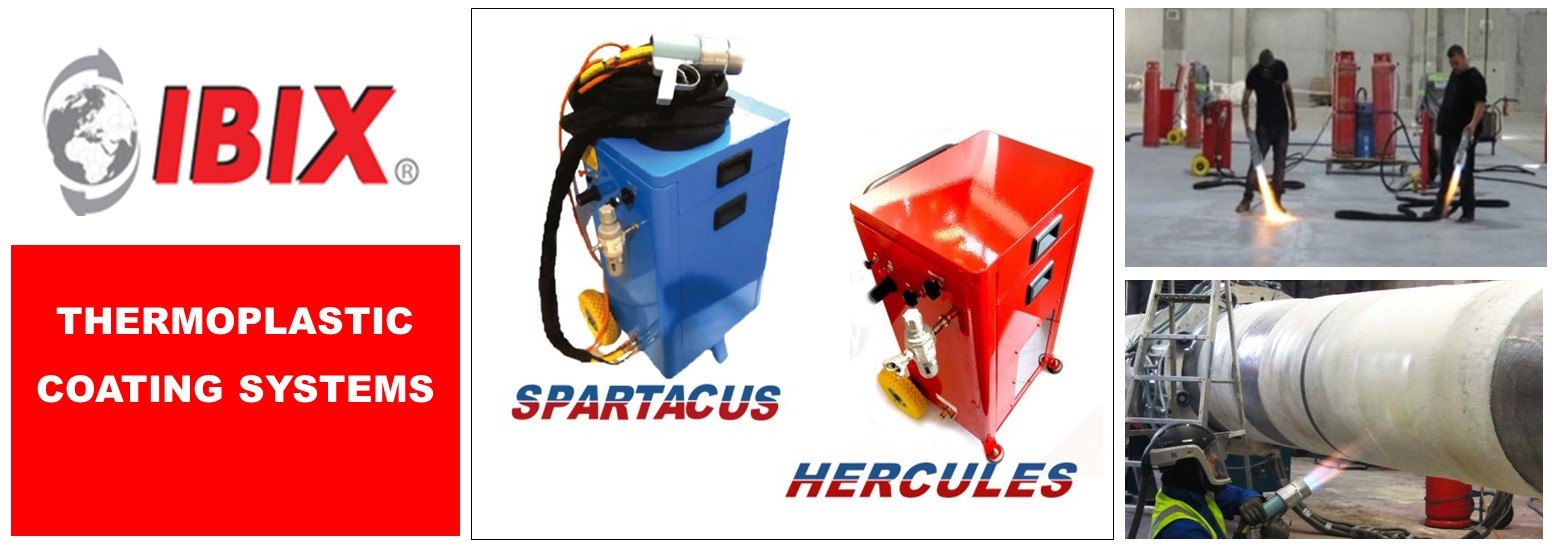

The Gladiator System consists of a portable unit applied by flame spraying thermoplastic powders for anti-rust treatments.

Gladiator Features:

- Compact size

- Easy portability

- Easy usability

- It provides the ability to apply in a wide variety of areas with high flow capacity features for high-rate applications.

The system, used with Propane gas, LPG, etc., and compressed air, also has various accessories depending on the nature of the work.

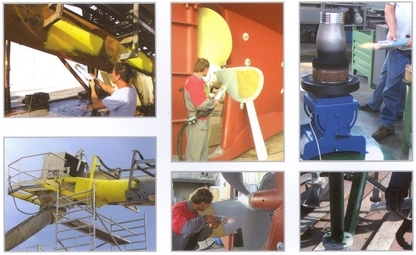

- Three different versions of application guns for high-capacity applications in large areas as well as work in small or hard-to-reach areas:

- Standard gun for medium-sized areas

- High-capacity gun for large areas

- Small gun with a grip and trigger mechanism, especially suitable for repairing polypropylene-coated joints and bends.

- Additional heating systems useful for coating thick parts or applications in very cold climates.

The system is resistant to sun, sand, salt, water, and substances causing common air pollution and chemical agents, while providing long-lasting anti-rust coating properties resistant to impacts, low temperatures, and UV rays. The product can be applied without using a primer. Perfect consistency in color is guaranteed. Gladiator has a wide range of application areas in various sectors;

CONTINUOUS DIELECTRIC INSULATION

- Separation from existing protection coating in underground structures

- Protection against electro and marine corrosion

OSMOTIC AND CORROSION BARRIER

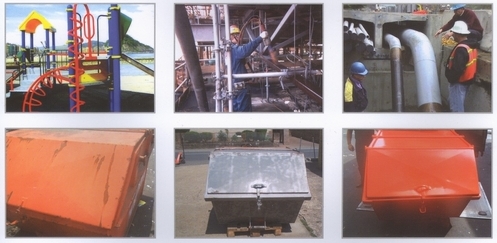

Buildings and bridges, offshore structures, and applications exposed to marine conditions, etc.

CHEMICAL RESISTANCE & PROTECTION OF METAL SURFACES FROM ACID EFFECT

- Coatings with high mechanical strength and resistance to abrasion

- Coatings for mineral deposits and treated wastewater discharge

OUTDOOR APPLICATIONS

Lighting poles, railings, fences, playground structures, swimming pools, gas/water distribution systems, food industry.

APPLICATION ADVANTAGES

The Gladiator System provides numerous benefits in application along with superior efficiency and quality performance:

- On assembled units that cannot be removed, in-factory or on-site applications: Pipes, tanks, joints and seams, general metal structures, equipment, etc.

- Repair and restoration of units coated with thermoplastic powder by other methods: Electrostatic, fluidized bed, extrusion.

- High efficiency: Up to 10 m²/h at approx. 200-250 microns with the standard gun, and up to 24-30m²/h at approx. 200-250 microns with the high-capacity gun.

- Versatile and flexible applications: Possibility to reach small and hard-to-access areas.

- Usability on all types of substrates: Metal, cement and concrete, fiberglass, plastic, wood, cardboard, anti-slip surface applications.

- Applicability of a wide variety of thermoplastics: Polypropylene, polyethylene, thermoplastic powders, PolyHotCote, various copolymer alloys.

- Single-step application: Direct application of thermoplastic powder onto the pre-prepared (sandblasted) substrate surface heated with a flame gun and/or additional heating gun.

- The coating is fully repairable and can be touched up later: The powder can simply be re-melted on the surface to repair the coating or increase thickness (without limit).

Non-Toxic and Eco-Friendly Solution:

Does not contain VOCs, halogens, isocyanates, and heavy metals, thus ensuring:

- Operator safety

- Application without overspray

- Enables coated units to be used without losing time.

- Long-term coating life: The coating life is longer compared to traditional systems, thus providing protection against corrosion in areas where other systems would fail.

- Application regardless of weather conditions: Flame spray applications of thermoplastic powders allow the coating to be applied in all kinds of weather conditions. This demonstrates the versatility of the Gladiator system.

- Cost savings: High-quality corrosion protection can be achieved with minimum downtime in on-site applications or large assembled structures.

- Resistant to corrosive chemical agents / protection against corrosion and oxidation: Repair, touch-up, and applications of thermoplastic coatings of unpainted objects.