Roval and Anti-corrosion Mechanism

ROVAL is a cold galvanizing product with high anti-corrosion performance, providing equivalent protection to hot galvanizing. ROVAL has a 96% zinc content in the dry film. ROVAL has a 96% zinc content in the dry film. |

|

ROVAL has a 96% zinc content in the dry film. Anti-corrosion performance is equivalent to hot-dip galvanizing.

High temperature is required for hot-dip galvanizing. However, ROVAL cold galvanizing can be performed even at room temperature. Ready-to-use ROVAL cold galvanizing has been used in Japan for more than half a century in the restoration of worn hot-dip surfaces and in the protection of metal surfaces such as steel against corrosion.

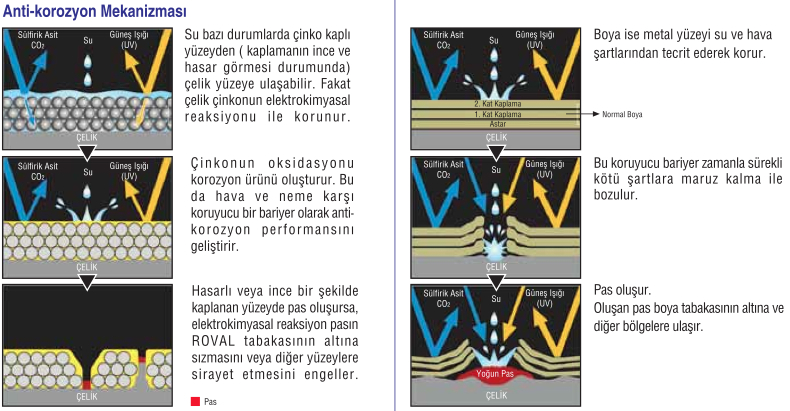

Anti-Corrosion Mechanism

ROVAL cold galvanizing product shows high anti-corrosion performance with high electrochemical reaction properties of zinc.

ROVAL protects steel against corrosion with its electrochemical reaction property of Zinc. Zinc provides cathodic protection on the metal surface by direct contact. The electrochemical reaction prevents the rust from seeping under the ROVAL film even if rust is formed on the damaged or finely coated surface.

Normal paints provide protection against water / air on the metal surface. If the paint layer is damaged or spilled, rust will reappear. The rust layer formed spreads from the bottom of the paint to the other regions.

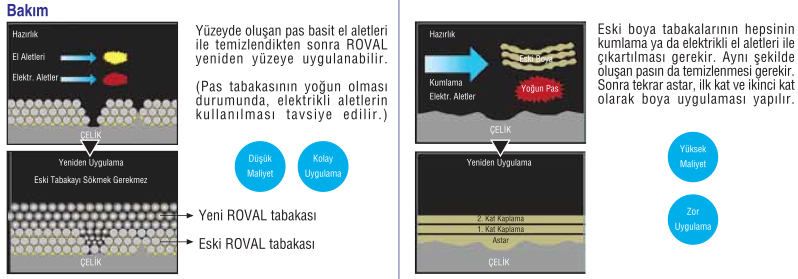

Maintenance

ROVAL can be applied directly to the surface only after the rust formed in the damaged area is removed. The new layer applied fuses with the old layer regardless of the time passing. A different layer does not occur. This significantly reduces maintenance costs.

| ROVAL (Anti-corrosion with Electrochemical Reaction) | Normal Paints (Anti-corrosion with Barrier protection) |

|

|

|

|

ROVAL Products Color Change Under Weather Conditions

Roval products have the same properties as galvanized materials exposed to weather conditions. These characteristics make the repair invisible.